|

|

Putting the Precision into Machined Components!

Despite quantity or complexity |

|

ATG supplies a range of precision machined components to OEMs in a variety of materials including stainless steel, aluminium, brass, alloys and plastics. These parts include gears and sprockets, plated pins and bosses, forged shafts and bearing housings for the agricultural, mining, construction, crushing & screening and material processing industries. Our factories only use the latest CNC technology providing multi axis CNC turning and milling capability up to several metres in length.

We are able to manufacture extremely complicated components and assemblies utilising our state of the art equipment and facilities. All parts are continually monitored and inspected through the manufacturing process to ensure they meet your exacting quality requirements and can then be shipped anywhere in the world. Whether you’re looking for a bespoke item or a large volume of identical parts ATG will work with your production teams to feed into your manufacturing timetable. This service can be tailored to meet changing schedules, multiple delivery dates and batch orders. Whatever size, complexity or volume of precision machined component you require leave it to ATG to deliver quality time after time. ATG makes global sourcing simple! |

Published in

News

|

|

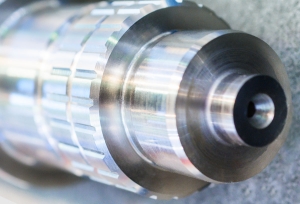

OEM Forged Shaft Supplier

All shafts undergo an 11 stage manufacturing process |

|

ATG supplies precision engineered shafts for the material processing, recycling, transportation and construction industries for a wide range of applications including eccentric and high end shafts for jaw crushers, pedestal shafts for cone crushers and transmission shafts for propellers.

Our shafts our made from high quality alloy steel and we supply in sizes up to 4 metres long, 400mm diameter and 2 tonnes in weight. All shafts undergo an 11 stage manufacturing process to ensure they more than meet our customers’ requirements. 1. Cast blank from steel ingot 2. Step forging 3. Normalising 4. Rough machining 5. Hardening and tempering 6. Mechanical properties testing 7. Semi finishing 8. Finish machining 9. Drilling and tapping 10. UT and dimensional check 11. Protection & packaging The step forging process gives the shaft excellent strength properties compared to other production methods. In addition, heat treatment is tailored to the chemistry to ensure that during quenching a fine grain structure is obtained to give maximum strength at bearing interfaces. Upon completion, all industrial shafts go through a final round of quality inspection before being shipped to our customers anywhere in the world. ATG looks after all the logistics and freight for you along with export documentation, customs entry, duty and final delivery. Whatever your shaft requirement you can rely on ATG! |

Published in

News